GMP型螺旋气流磨是我公司采用德国及美国进口技术研发而成,是为了对药用粉体进行粉体化处理而设计的,产品的D97粒径可低至2~3微米。分块易清洗的经典设计更保证了整个设备清理的简便与彻底性,特点在于简便的操作、优异的清洁度及很少的旋转部件。特别适用于医药行业的实验室操作,可以加工各类药品,包括 、原料药、中间体、辅料等。

同时,开发的新型生产线保留了所有经时间验证的优点并综合了新的特点以达到制药工业的要求,如易拆除,易清洗和 ,能达到CIP和SIP的生产能力。

由于医 料的活性越来越强,以及不可知性,在新药研发过程中,我们建议客户把设备集成在某种程度的隔离系统中,保护操作人员。我们可以提供完整的解决方案。

◆GMP01

·极低的批次粉碎产量,少3g起可投入使用

Smallest output for one batch, and 3g at least fora production

·极高的收集效率,产品99%可收集

Highest collection efficieney, and 99% of productcan be collected

·自分级装置,产品粒度d50:1~100μ之间可调

Self-classifying device, produet size variablebetween d50:1~100 micron

·用于新药研发和贵重药品生产

Used for new medicine development and expensivemedicine production

·无任何转动部件,拆装清洗极为方便

No any rotation part, and very easy to dismantleand clean

·粉碎用气量仅用0.5m³/min

Compressed air consumption is only 0.5m³/min

·可集成在隔离罩中

Can be integrated inside the isolation cover

·极少的占地空间,设备可参考右侧示意图,也可非标定制

With little floor space, the equipment can referto the schematic diagram on the right or can becustomized without standard

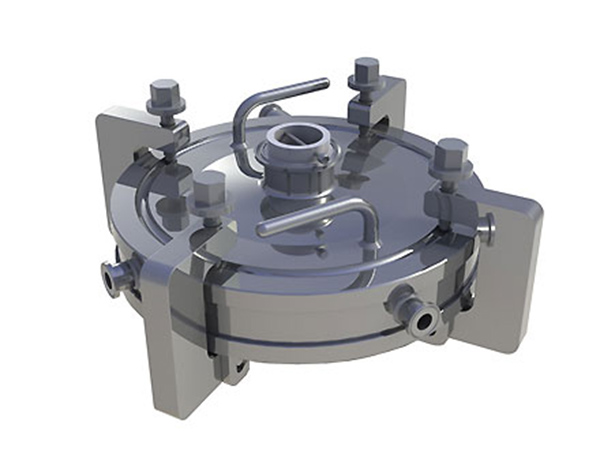

◆GMP02

·自分级装置,产品粒度d50:1~100μ之间可调

Self-classifying device, product size variable be-tween d50:1~100 micron

·极高的收集效率,产品99%可收集

Highest collection efficiency,and 99% of productcan be collected

·小时产量根据细度不同,一般在2~20kg/hr

Production capacity differs to the product fine-ness, normally around 2~20kg/hr

·适合注射级无菌药的生产

Suitable for the production of axenic medicine forinjection

·无任何转动部件,拆装清洗极为方便

No any rotation part, and very easy to dismantleand clean

·可实现CIP/SIP(可选择)

CIP/SIP design available(at your choice)

·极少的占地空间,设备可参考右侧示意图,也可非标定制

With little floor space, the equipment can refer to the schematic diagram on the right or can be customized without standard